Mastering the Art of Bolts and Machining: Developments and Best Practices

In the world of commercial production and engineering, the proficiency of fasteners and machining is a foundation of ensuring structural honesty, functionality, and long life in different applications. As modern technology breakthroughs and needs for performance and accuracy increase, remaining abreast of the most recent technologies and finest practices in fastening and machining comes to be critical. From the development of attaching modern technologies to the intricacies of picking one of the most ideal materials, the landscape of contemporary production is continuously progressing. Join us as we discover the latest innovations and explore the nuanced world of understanding bolts and machining, discovering key understandings and strategies that can raise your technique to design remedies.

Development of Fastening Technologies

Throughout the commercial revolution and right into the modern period, the development of attaching modern technologies has actually been noted by constant advancements in performance and reliability. Bolts, such as screws, rivets, and screws, play an essential role in various industries, consisting of vehicle, aerospace, construction, and electronics. The need for stronger, a lot more sturdy, and easier-to-install fastening services has actually driven development in the area.

One considerable growth has actually been the change towards precision machining methods to create fasteners with higher tolerances and remarkable performance. This shift has allowed makers to generate fasteners that meet rigorous top quality standards and offer enhanced resistance to corrosion and fatigue.

Moreover, the introduction of innovative products, such as titanium alloys and compounds, has transformed the capacities of fasteners. Fasteners and Machining. These products supply phenomenal strength-to-weight proportions, making them excellent for applications where minimizing weight is essential without endangering architectural stability

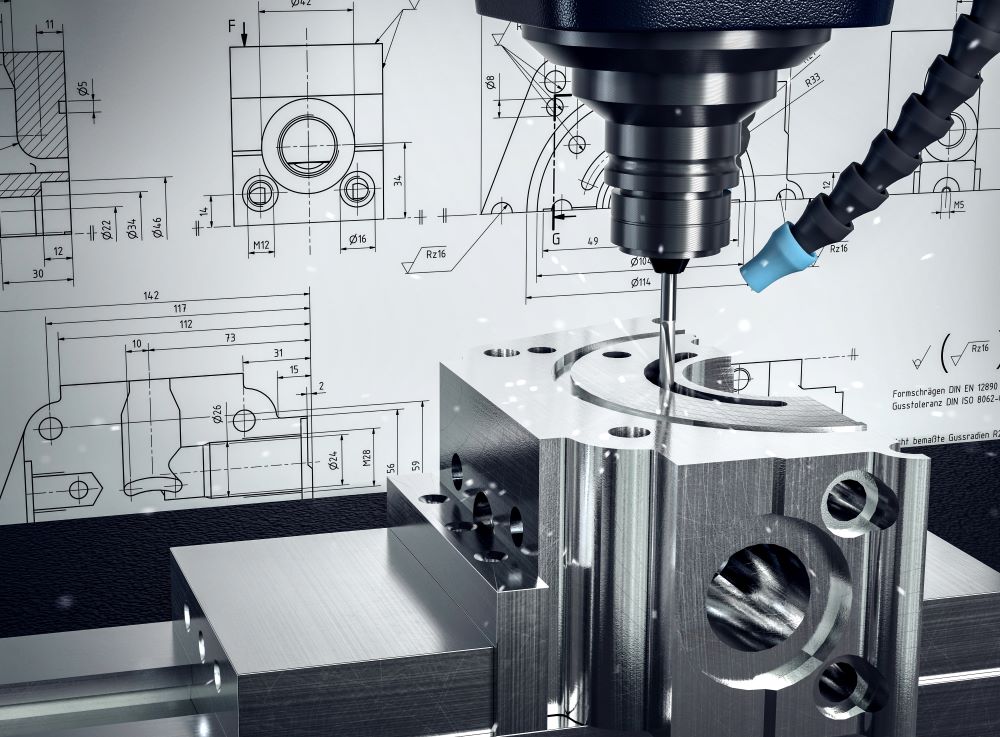

Developments in Machining Approaches

In the world of industrial manufacturing, the constant evolution of machining methods has led the way for unprecedented accuracy and efficiency in the manufacturing of fasteners. This accurate control enables suppliers to create complicated and detailed fastener styles with ease.

In addition, the adoption of multi-axis machining centers has allowed synchronised cutting operations from numerous angles, further enhancing efficiency and minimizing production times. By using these sophisticated machining techniques, manufacturers can meet the enhancing need for high-quality fasteners while preserving cost-effectiveness in their operations.

Choosing the Right Bolt Materials

Picking the ideal material for fasteners is an important choice that substantially affects the efficiency and durability of the constructed elements. When choosing the right fastener material, a number of elements have to be considered to make certain the resilience and integrity More hints of the end product. The material selected ought to be suitable with the ecological conditions the fasteners will certainly be subjected to, such as temperature level variants, moisture levels, and destructive elements.

Usual products utilized for fasteners include stainless-steel, carbon titanium, light weight aluminum, and steel, each offering distinct properties that suit various applications. Stainless-steel, for instance, is recognized for its deterioration resistance, making it excellent for aquatic or outside atmospheres. Carbon steel is a cost-effective option suitable for many general-purpose applications. Aluminum is lightweight and typically utilized in industries where weight is a crucial aspect. Titanium, on the other hand, is extremely strong and corrosion-resistant, making it ideal for high-performance applications.

Enhancing Accuracy in Machining

Attaining ideal accuracy in machining is crucial for making certain the quality and efficiency of machined components. To enhance accuracy in machining, manufacturers use a selection of advanced strategies and innovations.

In addition to CNC machining, the usage of advanced cutting devices and tool holders can also considerably improve accuracy. By focusing on accuracy in machining, manufacturers can accomplish exceptional product top quality, tighter tolerances, and boosted general efficiency of machined components.

Ideal Practices for Fastener Installation

Precision in machining plays an important duty in ensuring the integrity and long life of bolt setups. One essential facet is the proper choice of fasteners based on the certain application needs when it comes to finest methods for fastener setup. Making use of the correct kind, size, and product of bolt is necessary to guarantee ideal efficiency and sturdiness. Fasteners and Machining. Additionally, it is extremely important to follow supplier standards and advised torque values throughout the installment process to stop over-tightening or under-tightening, which can bring about premature fastener failure.

Additionally, ensuring that the bolt strings are complimentary and clean of particles before installment is essential to achieving a safe and secure and efficient connection. Making use of thread-locking substances or washers can likewise enhance the security of the fastener assembly. Normal examinations and maintenance of pop over to these guys bolts post-installation are suggested to recognize any potential concerns beforehand and prevent pricey fixings or substitutes in the future. By sticking to these best practices, makers can optimize the stability and efficiency of their fastener installations.

Verdict

Finally, the development of attaching technologies and developments in machining approaches have actually substantially improved the effectiveness and performance of bolt setup processes. websites By choosing the right fastener products and boosting precision in machining, producers can attain optimum lead to their operations. Following finest techniques for bolt installment is essential in ensuring the durability and integrity of settings up. Generally, grasping the art of bolts and machining entails constant advancement and adherence to ideal practices.

In the world of industrial production, the constant advancement of machining methods has paved the way for unprecedented accuracy and efficiency in the production of fasteners.Accuracy in machining plays a critical duty in guaranteeing the dependability and long life of bolt setups. When it comes to finest methods for bolt setup, one key aspect is the correct selection of bolts based on the specific application requirements. By picking the right bolt products and boosting precision in machining, manufacturers can achieve optimal results in their operations. On the whole, mastering the art of fasteners and machining entails continuous innovation and adherence to best techniques.